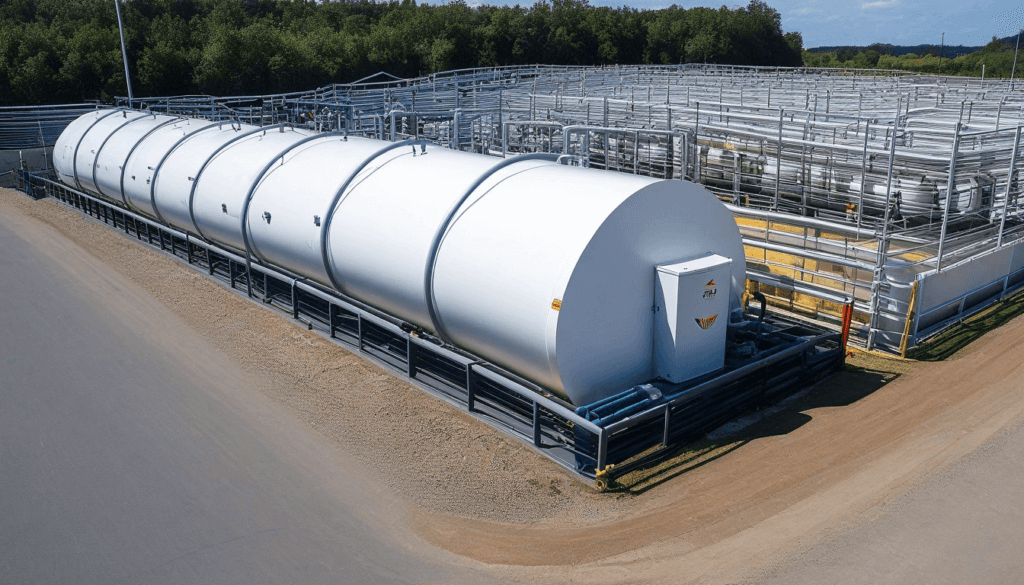

Fuel storage on construction sites is a critical aspect of project management, ensuring a reliable and safe fuel supply for construction equipment and machinery. The construction site fuel storage system typically involves the use of on-site fuel tanks or containers and often relies on various types of fuel, such as petrol gasoline and diesel.

Construction managers have to stick to environmental and safety regulations regarding fuel storage. Regular inspection and maintenance of fuel storage tanks are also mandatory to identify potential issues and ensure the integrity of the system.

Overall, a well-planned and properly managed fuel storage system contributes to the efficiency, safety, and success of construction projects by ensuring a reliable and secure fuel supply for the equipment and machinery involved.

Fuel Storage Best Practices

Proper fuel storage is crucial for safety and efficiency across industries. It helps prevent accidents like spills and ensures compliance with regulations, highlighting a commitment to responsible practices.

Maintaining fuel quality through proper storage preserves equipment performance, preventing downtime and costly repairs. Responsible storage also minimizes environmental impact and supports eco-friendly operations.

Preventing Water Contamination

Water can enter during transportation or if there are any leaks in the storage system. Detecting and removing water promptly is essential because water in fuel can cause engine issues, corrosion, and microbial growth.

As temperatures drop, water in the fuel can freeze, leading to blockages and operational problems. Ensuring tanks are properly drained and equipped for winter conditions safeguards against fuel contamination and keeps equipment running smoothly during colder months.

Ensuring Tank Cleanliness

Sediment and water tend to accumulate at the tank’s base, posing a risk of fuel contamination. Annual bottom-of-the-tank inspections involve assessing the tank’s interior for any buildup, corrosion, or signs of degradation.

Cleaning schedules depend on factors such as the type of fuel, environmental conditions, and usage patterns. Regular tank cleaning can prevent the accumulation of contaminants, safeguard against corrosion, and extend the tank’s lifespan.

Inspecting Tank Accessories

Properly functioning gauges ensure accurate fuel level monitoring, while well-maintained hatches, vents, and fill caps prevent the entry of contaminants like dirt and water.

Regular inspections and swift replacement of any worn-out parts contribute to the longevity and reliability of the entire fuel storage system. Components such as seals, gaskets, or mechanical parts can degrade over time, compromising the sealing and protective functions of tank accessories.

Construction Site Fuel Safety Measures

Adhering to safety protocols for construction site’s fuel storage tanks is super important for the well-being of workers and the protection of equipment.

Approved Containers & Temperature Considerations

Department of Transportation (D.O.T.) approved containers are designed and tested to meet strict safety standards, ensuring that above ground fuel tanks can withstand the demands of transportation and storage without compromising the integrity of the fuel.

Controlling temperatures helps prevent fuel degradation, phase separation, and the formation of wax or gel in cold conditions. The ideal temperature to store fuel is 70 F for a prolonged shelf life.

Security Measures

Controlling access to fuel storage on construction sites enhances safety and avoids potential environmental hazards. Using a containment berm is an effective spill-prevention measure, especially for larger fuel storage areas. In the event of a spill, the containment berm helps in confining the fuel, allowing for prompt cleanup and minimizing the impact on the surrounding area.

Maintaining Safe Distance

Construction sites often have equipment and activities that can generate sparks or flames. It’s imperative to establish clear safety zones and prohibit smoking or the use of open flames near construction site fuel storage tanks.

Being aware of emergency contact information is also vital for quick response in case of unforeseen incidents. This information includes the nearest medical facilities, fire departments, and relevant site contacts.

Hose Maintenance and Cap Security

Inspect hoses for wear, abrasions, or signs of deterioration, and replace any damaged components promptly.

The fuel tank cap serves as a protective barrier, preventing contaminants from entering the fuel storage tank. A compromised cap can allow moisture, dirt, or debris to enter the tank, leading to fuel contamination and potentially causing issues with equipment operation.

Emergency Preparedness

Regular inspections help identify potential issues early on, ensuring equipment reliability and minimizing the risk of emergencies. Additionally, the use of caps is essential to prevent contaminants from entering the tanks, thereby maintaining fuel quality and reducing the risk of spills.

Having a forklift readily available for tank movement enhances emergency response capabilities. In the event of needing to relocate fuel storage tanks, a forklift facilitates swift and safe movement.

Implementing safety measures during fueling processes is crucial for emergency preparedness. This includes following established protocols for fuel transfers, using appropriate personal protective equipment (PPE), and maintaining a safe distance from ignition sources.

General Fuel Safety Protocols

The safety of construction site fuel storage tanks is not just a legal requirement but a critical element for protecting both personnel and assets.

The staff should be trained in evacuation procedures to ensure a swift and organized response in case of emergencies. Disregarding safety measures increases the risk of workplace accidents, leading to injuries, equipment damage, and potential legal consequences.

Handling Accidental Spills

In the event of an accidental fuel spill, immediate and proper fuel action is crucial to minimize potential harm. Protocols for skin and clothing safety involve swiftly removing contaminated clothing and thoroughly washing exposed skin with soap and water.

In the aftermath of a spill, all ignition sources must be promptly eliminated. This includes shutting down equipment, extinguishing open flames, and controlling any potential sparks.

Equipment Shutdown for Safety

One crucial aspect of equipment safety involves shutting them down to prevent static electricity ignition risks. When refueling, static electricity can build up, posing a potential ignition hazard. Running engines can generate heat and sparks, increasing the potential for accidents.

Grounding equipment and ensuring proper bonding between the fuel source and the equipment further reduces the likelihood of static electricity-related incidents. Bonding is the process of creating a conductive connection between two objects. By ensuring that both the fuel source and the equipment have a common ground, any potential static charge can dissipate harmlessly.

Safe Fuel Transportation

Ensuring the safety of fuel during transportation involves closing shut-off valves and securing the fuel source effectively. Shutting off valves prevents fuel from flowing during transport, minimizing the risk of leaks or spills.

Secure fuel containers on vehicles or trailers in an upright position. This reduces the risk of fuel sloshing or shifting, maintaining stability and preventing potential accidents.

Proper Fuel Disposal

Construction sites should cooperate with local authorities to determine and implement responsible disposal methods. Open communication with local authorities ensures compliance with environmental regulations and contributes to sustainable fuel management and best handling practices.

Advanced Fuel Monitoring and Management Tools

Fuel monitoring has entered a new era with cutting-edge technological innovations. These advancements are transforming the way construction sites manage and optimize their fuel usage.

The latest innovations include real-time monitoring systems that leverage sensors and IoT technology to offer a comprehensive view of fuel-related data, enabling informed decision-making.

Telematics not only monitors fuel consumption but also tracks the location and condition of vehicles and machinery.

Benefits of Remote Fuel Monitoring

Through cloud-based platforms and mobile applications, construction site managers can remotely monitor fuel levels, consumption patterns, and equipment performance from anywhere.

Construction managers can identify trends, set benchmarks, and implement strategies to minimize fuel expenses, contributing to overall budget savings.

Utilizing Technology for Fuel Management

Modern fuel management leverages innovations in fuel tank monitoring through user-friendly apps and advanced remote systems.

Remote monitoring allows for immediate response to unexpected events, ensuring rapid intervention in case of fuel leaks or other emergencies. By analyzing historical data, these tools help anticipate fuel needs and proactively address maintenance requirements.

Final Advice on Construction Site Fuel Storage Efficiency

From a well-planned fuel storage design and installation to rigorous safety protocols, regular maintenance, emergency fuel needs and embracing advanced technologies, these practices collectively contribute to an efficient, secure, and environmentally responsible fuel management system.

Adhering to regulations and using a reliable fuel fleet management service such as Fuel Logic not only improves day-to-day operations but also positions construction sites for long-term success.

With Fuel Logic, you can navigate the complexities of construction sites with confidence, ensuring a seamless, calculated mobile delivery approach to fuel storage and without worry because of the mobile fleet fueling service we provide.

For more detailed information or specific inquiries, please refer to Fuel Logic – FAQ.

FAQ – Frequently Asked Questions

How often should fuel storage systems be inspected?

Typically, a thorough inspection is recommended at least annually. However, more frequent checks, such as quarterly assessments, ensure early detection of potential tank issues and adherence to safety standards. To lessen the hassle, it is very important to choose the right fuel supplier to eliminate problems and get quality fuel.

What are the common causes of fuel contamination?

Common causes of fuel contamination include water ingress, microbial growth, sediment buildup, and exposure to air. Poor storage conditions, lack of proper maintenance, and use of contaminated equipment contribute to fuel contamination.

How much fuel can be stored on a construction site?

Factors such as the size of equipment, project duration, and estimated fuel consumption influence the construction site fuel storage needs. Compliance with local regulations is essential when determining storage limits. According to OSHA, this limit is set to 1100 gallons in an area, where anything above this amount will be considered hazardous.

What are the safety requirements for diesel storage?

Safety requirements for diesel storage involve using D.O.T.-approved containers, proper ventilation, and adherence to fire safety regulations. Diesel storage areas should have fire extinguishers, clear signage, and appropriate containment measures to prevent spills.