Handling, storing, and moving fuel is a regular part of many industries, including various fleet companies and the agriculture sector. Gasoline and similar fuels can easily catch fire because they are highly flammable. So, following safety guidelines is crucial to keep equipment safe and prevent serious accidents.

Adhering to fuel safety precautions ensures the well-being of workers and prevents catastrophic incidents. The fuel safety measures contribute to environmental protection by minimizing the potential for spills, leaks, and other incidents that could harm ecosystems.

Furthermore, compliance with fuel system safety precautions is also essential for legal reasons. Governments and regulatory bodies establish guidelines to ensure the responsible handling, storage, and transportation of fuels.

Importance of Fuel Safety

Fuel safety is important for a few reasons:

Prevention of Accidents

Following safety guidelines is like a shield that helps us avoid big problems like fires and explosions. When dealing with flammable fuels like gasoline, one must follow safety instructions for protection from severe accidents and injuries.

Environmental Protection

It’s not just about keeping ourselves safe; it’s also about being kind to our environment. By handling fuels carefully, we lower the chances of spills and leaks that could hurt nature and wildlife.

Regulatory Adherence

Following fuel safety precautions is essential to stay on the right side of the law. It prevents legal issues and shows our commitment to being responsible custodians.

Understanding Fuel Safety Hazards

Understanding fuel safety hazards means recognizing potential risks linked to fuel handling, storing, and utilizing. It involves identifying situations where flammable substances like gasoline or diesel, when not handled carefully, could lead to fires or explosions.

Here are some potential risks and hazards associated with improper fuel handling:

- Fire or explosion risks during improper storage and handling of fuels.

- Health dangers from exposure to hazardous substances.

- Increased potential for falls and injuries during fuel handling.

- Environmental and safety concerns from fuel leaks and spills.

- Health issues arising from inhaling petrol fumes, including dizziness and headaches.

- Skin irritation and burns resulting from prolonged contact with fuel.

Comprehensive Fuel Safety Precautions

Here are some primary fuel system safety precautions that one must follow to avoid any mishap:

Storage Guidelines

When storing fuel, keep it safe by not smoking around it and sealing the container tightly. Pour fuel outside in an open area using a spout or funnel to avoid spills. These simple steps ensure everything stays safe when dealing with fuel storage.

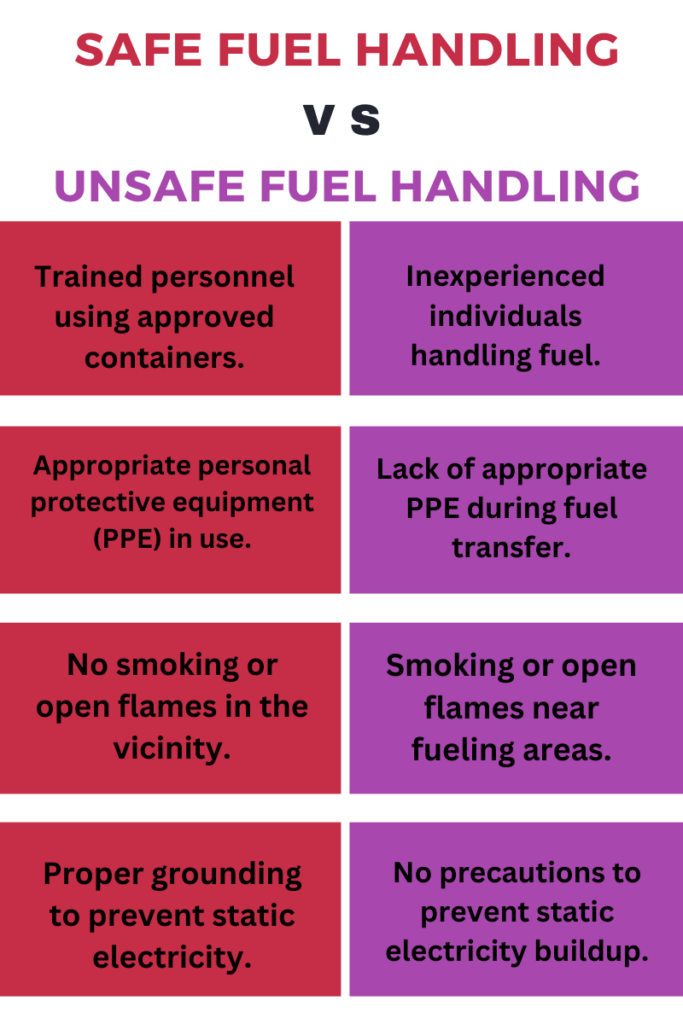

Handling Procedures

When you are handling fuel, here’s what you should do to keep things safe:

- Use approved containers to avoid leaks.

- Don’t start a siphon with your mouth; use a pump or hose instead.

- Never walk away from the fuel pump while refueling.

- Keep a fire extinguisher close.

- Check that the fill valve is open.

- Stop transferring fuel before it overflows.

- Don’t overfill mobile refueling tanks or vehicle fuel tanks.

Maintenance Measures

Maintenance measures focus on ensuring safety through careful planning and regular actions:

- Plan the work area for safety.

- Ensure proper ventilation in fuel storage areas.

- Check emergency equipment functionality regularly.

- Conduct ongoing training for fuel handling personnel.

- Perform final safety checks before completing maintenance tasks.

- Update safety documentation regularly.

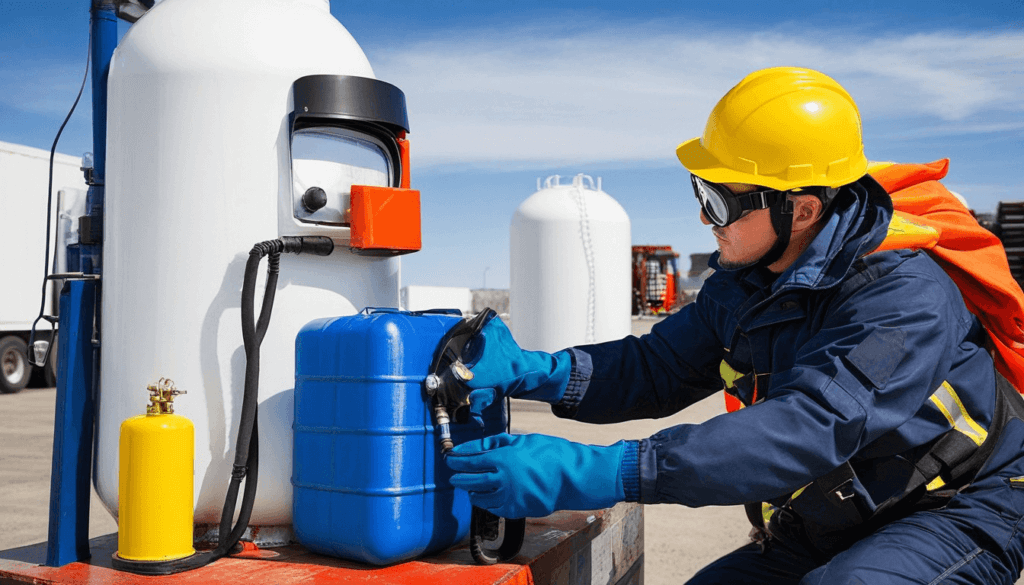

Safety Equipment

Ensure safety while storing and moving fuel with the following safety gear:

- Wear high-visibility, fire-resistant clothes.

- Use safety footwear.

- Keep spill response kits nearby.

- Use grounding equipment to prevent static electricity.

- Utilize approved fuel transfer pumps.

Emergency Protocols

In case of a fuel-related emergency, follow these steps:

- Evacuate the area immediately.

- Notify nearby individuals about the trouble.

- Call emergency services.

- Block off the affected area.

- Use emergency tools if needed.

- Follow emergency plans.

- Provide first aid if necessary.

- Cooperate with authorities.

Safety Measures for Handling Fuel in the Workplace

Specific diesel fuel safety precautions are essential, especially at construction sites where diesel fuel is used in bulk. It includes using approved containers, maintaining proper ventilation, implementing no-smoking policies in fuel areas, and inspecting storage equipment regularly.

Employee training also plays a pivotal role in this regard. The staff must be well-informed about potential hazards and encouraged to report any safety concerns promptly. They must wear safety equipment, such as goggles, gloves, and fire-resistant clothes.

Furthermore, you should maintain accessible fire extinguishers, emergency showers, and spill response kits in the workplace. Above all, practicing evacuation procedures in the workplace, including managing fuel securely, helps everyone stay prepared and aware.

Storing and Handling Fuel

Understanding the importance of proper fuel storage and handling is mandatory for a safe and secure workplace. When done correctly, it minimizes the risks of accidents and undue losses.

Storage Quantity

When storing fuel, you must assess and hold only the required amount of fuel to avoid unnecessary risks and ensure a secure environment. It provides a safer workplace by minimizing the chances of disasters and hazards associated with excessive fuel storage.

Approved Containers and Storage

You must use suitable containers and storage facilities to prevent leaks, spills, and potential hazards linked to improper storage. So, assess your needs and choose the appropriate and reliable containers for your business. For example, a sturdy, approved steel or polyethylene container with proper ventilation is ideal for handling diesel.

Safety Measures During Handling

Prioritize safety when handling fuel by wearing Personal Protective Equipment (PPE). One must prohibit smoking near the fueling sites and keep spill response kits within reach. These measures help secure the workplace environment and safeguard the well-being of individuals.

Receiving Fuel

The following fuel safety measures are paramount when receiving fuel:

Smoking Prohibition

It’s imperative to strictly avoid smoking in areas where fuel is being received. It is to prevent possible hazards associated with open flames and fuel vapors.

Spill Preparedness

Having well-established protocols ensures a swift and effective response to manage any spills promptly. You can stay ready for fuel spills by making sure your employees get regular training on handling fuel and responding to spills. Keep spill kits with all the necessary stuff handy and set up containment systems to quickly limit environmental harm.

Closed Fuel Caps

After you receive fuel, make sure to close the containers securely. Tightening your fuel caps is crucial to avoid fuel leaks or evaporation, saving you money and maintaining a cleaner environment. It also ensures the fuel is properly contained.

Proper Positioning

Keep the fuel tank on the ground or on a stable surface. Placing it at a low, easy-to-reach height reduces the risk of spills and accidents. This way, you have better control and make fuel reception safer, minimizing the chance of mishandling.

Fueling Vehicles and Equipment

Fueling vehicles and equipment requires careful attention to safety, and here are some important considerations:

Reference Operating Manuals

When fueling up your vehicles or equipment, always follow the manuals. The manuals give you important information on how to do it correctly for each car or equipment. Following these guidelines makes the fueling process smooth and safe.

Emergency Preparedness

In emergencies, rushing can lead to mistakes. Make sure to familiarize yourself with emergency procedures to prepare yourself for any challenges during fueling. Additionally, if you ever need emergency fuel delivery, it’s crucial to abide by safety rules.

Safety Measures During Fueling

Make sure to park vehicles and equipment at their designated fueling areas. Turn off the engines completely, and never smoke during this process. Use the right fueling tools and have spill response kits ready in case of accidents.

Filling Portable Containers

When filling up portable containers, use containers approved for the job, fill them sparingly, and ensure they are on a stable surface. Always use the right funnels and handle fuel attentively to avoid spills and undue troubles.

Environmental Impact and Regulatory Compliance

Improper fuel handling can harm the environment, causing soil and water contamination, air pollution, and ecosystem damage. These consequences don’t just affect nature; they also pose risks to human and animal health.

Studies have found that exposure to oil and gas from spills can lead to respiratory issues, liver damage, weakened immunity, reproductive problems, and increased cancer risks. Therefore, strict rules and standards are in place at local, regional, and national levels to prevent these problems.

Regulatory requirements and compliance standards in fuel management encompass a set of rules and guidelines established by authorities to ensure the safe and responsible handling of fuels. They emphasize avoiding spills and ensuring emergency readiness. They include storage, transportation, and spill response protocols to prevent environmental harm and protect public safety.

Above all, emphasizing the need for eco-friendly practices is also critical. It involves promoting the use of sustainable fuels and implementing pollution prevention measures. Proper fuel management practices also encourage adopting technologies that minimize the ecological impact of fuel production, distribution, and consumption.

Importance of Education and Training

Education and training are indispensable elements in ensuring safe fuel handling. These initiatives equip personnel with the necessary knowledge and skills. The workers and employees who have received proper training play a crucial role in reducing the occurrence of fuel spills and mitigating environmental risks associated with such incidents.

Well-trained individuals enhance the safety and efficiency of fuel-related activities. They actively contribute to a culture of responsibility, safeguarding themselves, their colleagues, and the environment. Their expertise extends to keeping their team and equipment safe while ensuring a secure operational environment.

Challenges and Solutions

Ensuring effective fuel safety measures can be challenging, but practical solutions exist. One challenge is getting everyone to follow safety rules consistently. The solution involves comprehensive training, clear communication, and regular safety checks.

Another challenge is managing the environmental impact of fuel activities. Innovative technologies, like advanced spill detectors and eco-friendly disposal methods, help tackle these concerns.

When safety protocols during fueling become inconsistent, turn to Fuel Logic’s off-road diesel delivery service. It streamlines the process, ensuring controlled and efficient fueling for specific equipment.

Conclusion

Fuel safety precautions are beyond mere guidelines; they reflect a dedication to safety, adherence to regulations, and environmental guardianship. Primarily, preparedness for fueling emergencies is a crucial aspect that guarantees a prompt and efficient response in unexpected scenarios.

You can also turn to Fuel Logic, a fuel delivery service that not only offers the convenience of doorstep fuel delivery but also strongly emphasizes fuel management measures for workplace safety. In addition to providing easy fuel access, Fuel Logic prioritizes safety, working to mitigate potential fuel mishaps and ensuring the well-being of individuals in the workplace.

Ultimately, these precautions serve as the foundation of successful fuel safety and management. They shape a workplace that emphasizes security, efficiency, and thorough care.

FAQs (Frequently Asked Questions)

What are the best practices for fuel storage?

Adhere to the following practices for safe fuel storage:

- Use approved containers and portable fuel tanks.

- Avoid storing near exits or passages.

- Store only the necessary amount of flammable liquid.

- Limit hose length to 50 feet during fuel transfer.

- Store up to 25 gallons for rooms, or use an approved storage cabinet.

What PPE is required for handling fuel?

One must use specific protective gear known as Personal Protective Equipment (PPE) for handling fuel. This gear encompasses eye protection, hearing protection, hand and foot protection, and flame-resistant clothing (FRC). Wearing these safeguards ensures safety and prevents extreme hazards while working with fuels.

What to do during a fuel spill?

If a fuel spill occurs, immediately ensure everyone’s safety. Evacuate the area urgently and inform the fuel spill cleanup team. Furthermore, identify the spilled fuel and create a barricade around the spill (if possible).

Clean up fuel spills by using dry absorbents. Spread them over the spill, and once they have soaked up the fuel, sweep up the materials for proper disposal.

Why is fuel safety compliance important?

Fuel safety compliance is vital for personal safety, environmental protection, and legal adherence. It is important to emphasize the importance of compliance training and having designated operators at each facility. This approach ensures a secure environment and minimizes troublesome hazards associated with fuel handling.